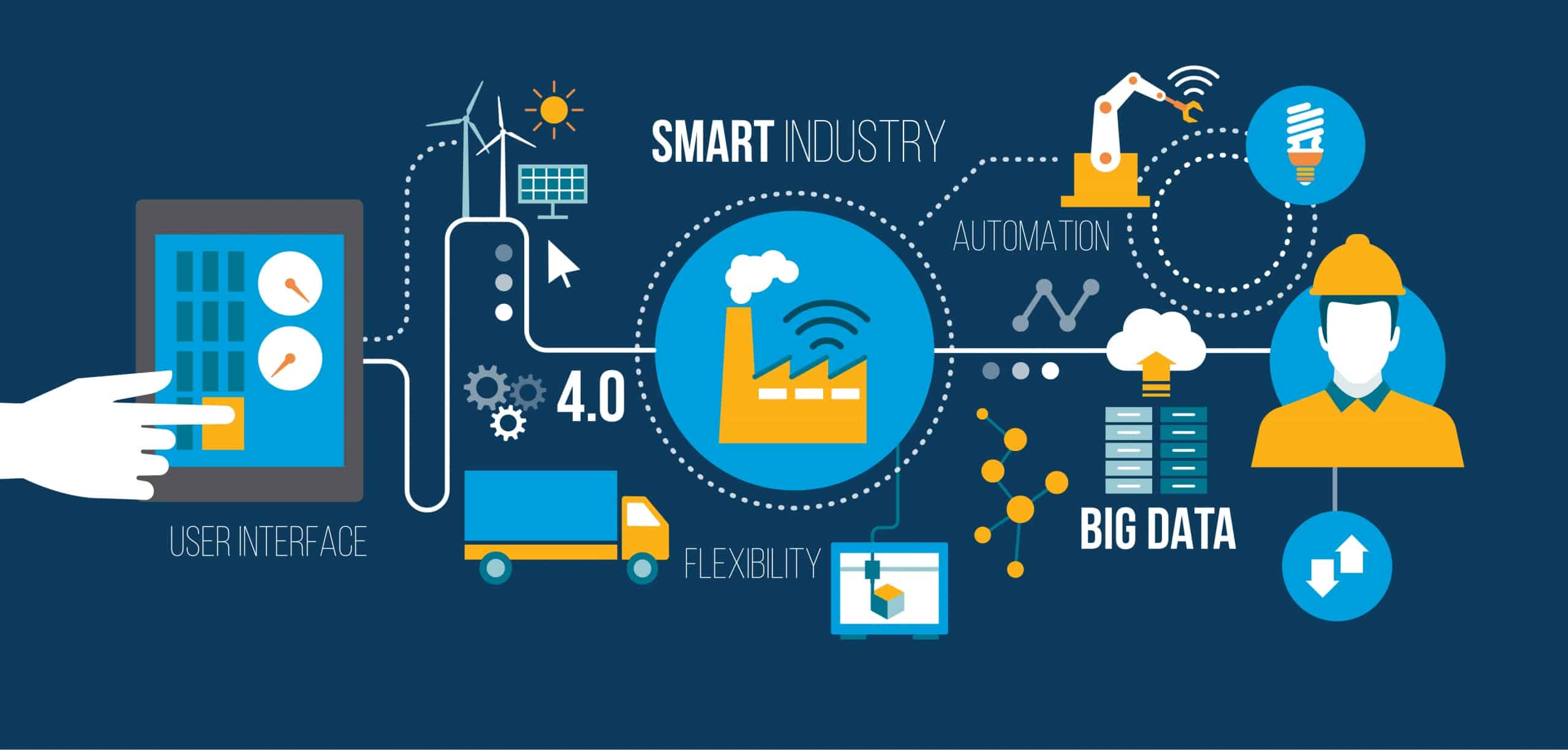

In recent years, there has been a significant shift in the manufacturing industry towards automation and digitization. This trend is referred to as Industry 4.0, or the fourth industrial revolution. Smart Industry 4.0 is transforming manufacturing by using advanced technologies like artificial intelligence (AI), the internet of things (IoT), and robotics to streamline operations, reduce costs, and increase efficiency. In this blog post, we’ll explore how Smart Industry 4.0 is changing the face of manufacturing and what it means for the future of the industry.

1. Connected factories:

Smart Industry 4.0 is characterized by the integration of digital and physical systems. This means that machines, equipment, and other devices are connected to the internet and can communicate with each other. This connectivity allows for real-time data analysis, predictive maintenance, and the optimization of manufacturing processes.

2. Advanced analytics:

Another key feature of Smart Industry 4.0 is the use of advanced analytics. This includes technologies like machine learning, predictive modeling, and data visualization. By analyzing large amounts of data, manufacturers can gain valuable insights into their operations, identify inefficiencies, and make data-driven decisions.

3. Autonomous systems:

Smart Industry 4.0 is also characterized by the use of autonomous systems, such as robots and drones. These systems can perform tasks that are dangerous or difficult for humans, and can work around the clock without needing breaks. This leads to increased efficiency and productivity.

4. Customization and flexibility:

One of the biggest benefits of Smart Industry 4.0 is the ability to customize products on demand. With the use of advanced analytics and automation, manufacturers can quickly and easily adjust production lines to meet changing demand. This means that they can respond quickly to customer needs and preferences, and can create personalized products at scale.

5. Sustainability:

Smart Industry 4.0 also has the potential to improve sustainability in the manufacturing industry. By reducing waste, optimizing energy use, and improving supply chain efficiency, manufacturers can reduce their environmental impact and improve their bottom line.

Conclusion:

Smart Industry 4.0 is revolutionizing manufacturing by using advanced technologies to improve efficiency, productivity, and sustainability. By connecting factories, using advanced analytics, and implementing autonomous systems, manufacturers can optimize their operations and respond quickly to changing demand. As technology continues to advance, we can expect to see even more innovations in the manufacturing industry, making it more efficient, cost-effective, and sustainable.